Gas firing | |||

I based the design on photos in Ian Gregory's book Alternative Kilns (A&C Black 2005) for the raku rocket on the basis that this should be reasonably gas tight and easy to insulate. The liner components, chamber, lid and flue, were thrown using a succession of large coils to build up the height and then separately thrown ports added. |  |

||

|---|---|---|---|

|

The lid and chamber were too large to fit in our electric kiln so they were fired by building a flat pack kiln arund them. |

||

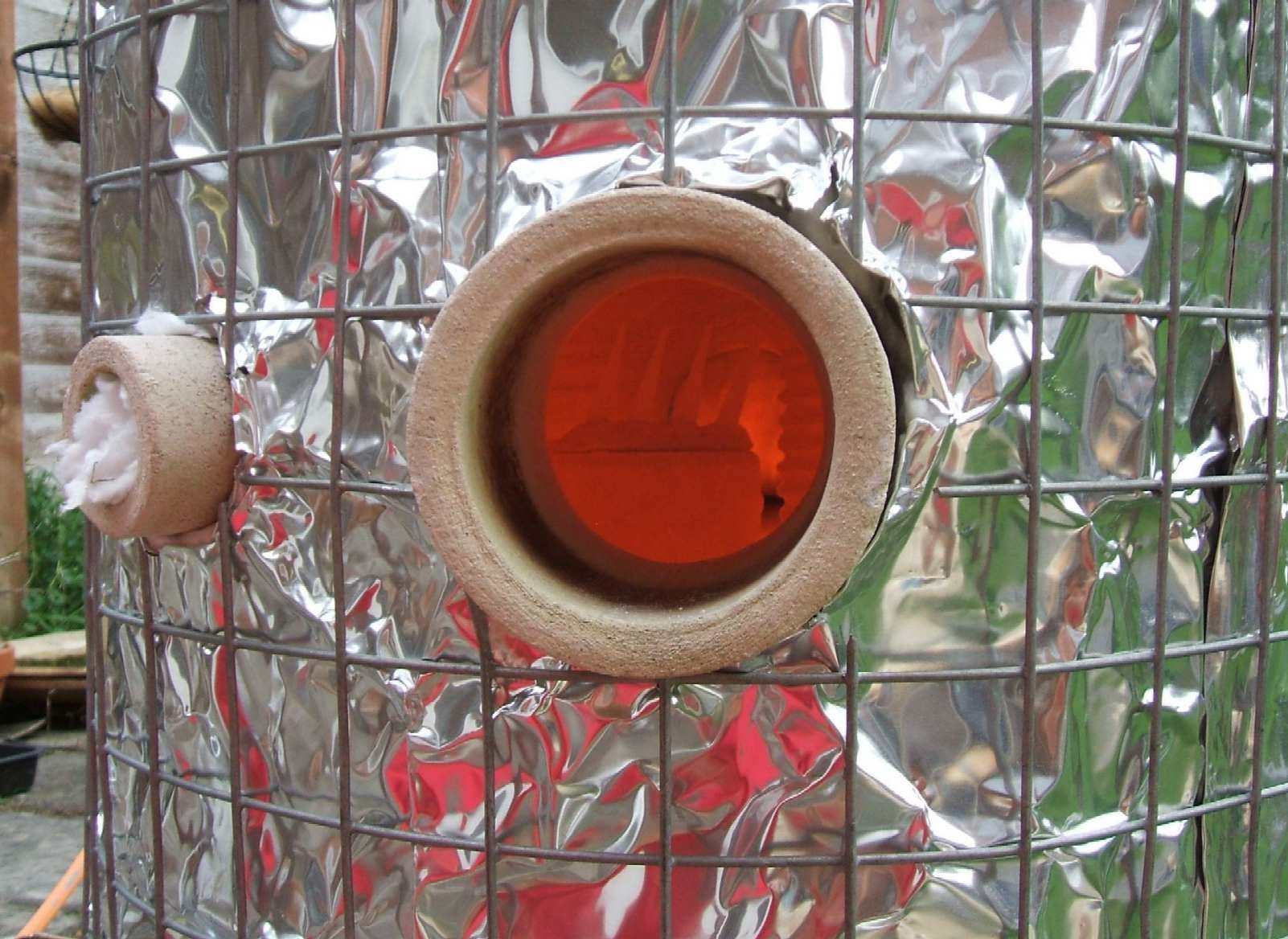

Once fired, the chamber and lid were insulated with ceramic fibre, aluminium sheet and weldmesh or chicken wire so that firing could commence |  |

||

|

| ||

After firing the kiln was stopped up and left to cool overnight. This is a view through the flue vent in the lid. The reduction was not very strong but the two mugs with a shino glaze came out quite well with a range of greens, greys and silver indicating some carbon capture

|  |

||